We all know that “mouthfeel” or “touch” can make or break a product. But in a lab, “it feels sticky” isn’t data. You need numbers. You need repeatability.

Whether you are formulating a new plant-based meat alternative in a food tech startup or ensuring the break-force of pharmaceutical tablets meets export regulations, you need an objective way to measure what customers feel. That’s where we come in.

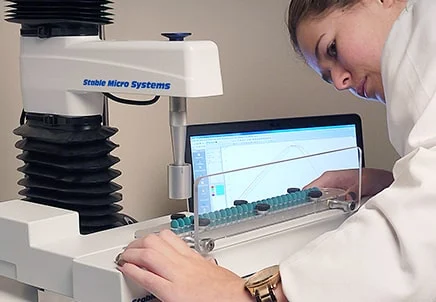

As a leading provider of the texture analyser Singapore market trusts, Lee Hung Scientific connects you with the gold standard in physical property testing. We don’t just supply equipment; we help you quantify the “unquantifiable.”

Aside from being an instrument supplier, we also conduct Texture Analysis workshops and see it as our goal to bring all our local education institutions, commercial industries and R&D Food Tech centers to perform Texture Analysis at a professional level. Just knowing about Total Profile Analysis (TPA) isn’t enough! Many users lack the true understanding in the principles behind TPA and have miss used this method erroneously! Our application engineer is here to support your texture requirements.

Which System Fits Your Lab?

Choosing a texture analyzer isn’t about getting the most expensive machine; it’s about matching the instrument to your daily reality. Here is how our lineup breaks down for real-world applications:

- The Daily Workhorse: TA.XTplusC

For the lab that tests a bit of everything.

This is our “Swiss Army Knife.” If your team switches from testing the firmness of gels in the morning to the snap of biscuits in the afternoon, the TA.XTplusC is your answer. It handles the vast majority of food, cosmetic, and pharmaceutical applications with a single column design that doesn’t hog bench space. It’s the universal choice for a reason.

- Quick & Simple QC: TA.XTExpressC

For when you just need the answer, now.

Not every operator is a scientist, and they shouldn’t have to be. The TA.XTExpressC is stripped down for speed. It’s perfect for the production floor where you need fast, pass/fail quality control without navigating complex software menus. It keeps your line moving.

- The Heavy Lifter: TA.HDplusC

For high-force requirements.

Some products fight back. If you are testing high-strength adhesives, heavy gels, or packaging materials that require significant force to puncture or compress, the dual-column TA.HDplusC gives you the extra muscle you need without sacrificing precision.

- Powder Flow Analyser

Because powders are unpredictable.

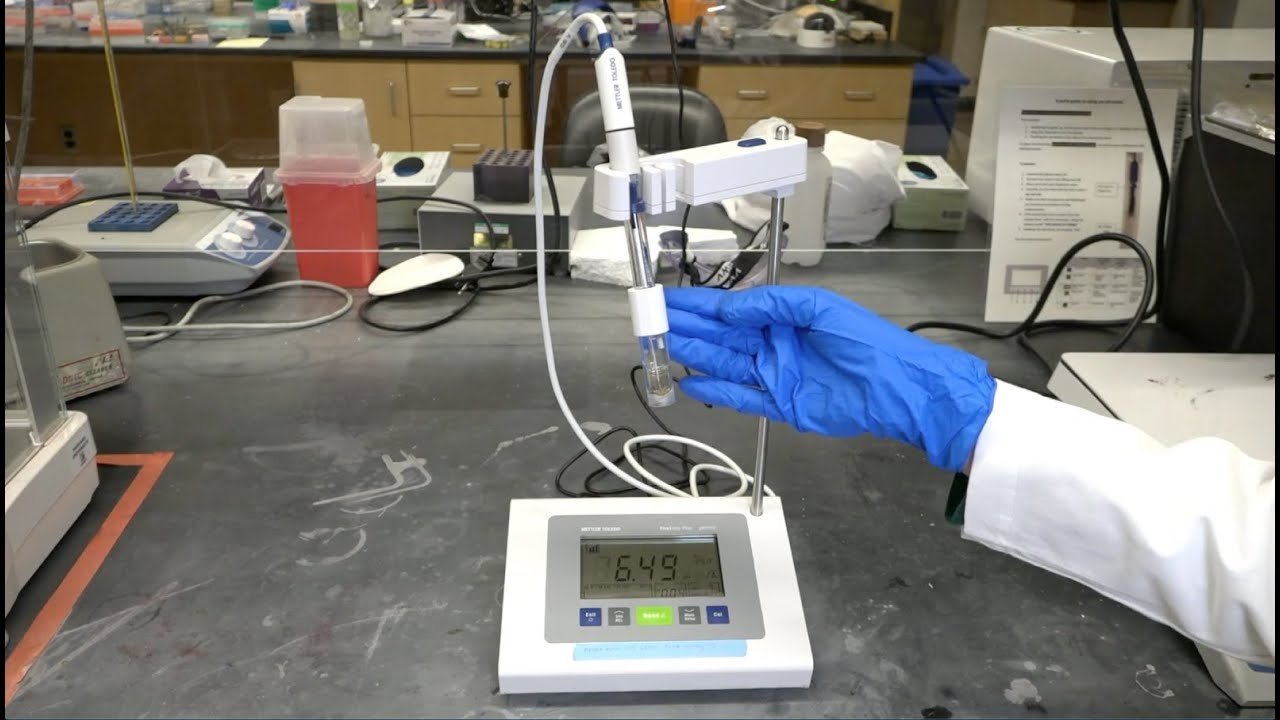

Humidity in Singapore can wreak havoc on powder flow. Caking and erratic flow rates can stall production lines. Our Powder Flow Analyser helps you predict these issues before they happen, ensuring your hoppers keep moving and your mixtures stay consistent.

Why Singapore R&D Teams Choose Lee Hung

Buying a high-end instrument from an overseas catalogue is risky. Who sets it up? Who calibrates it next year?

We bridge that gap. We understand the local landscape—from the specific compliance needs of Singapore’s food manufacturing hubs to the rigorous standards of our local polytechnics and universities.

- Local Support: No waiting for different time zones when you have a technical question. We also conduct Texture Analysis workshops to bring your theory and knowledge to the next level.

- Application Expertise: We help you figure out how to hold that awkward sample and which probe will give you the data you need.

- Long-term Reliability: We are here for the life of your machine, ensuring your data remains audit-ready year after year.