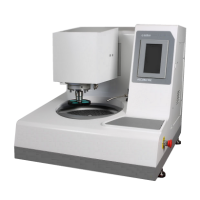

Product Details

MICRACUT 152 precision cutters are used for precise and deformation-free cutting of “Metals, Ceramics, Electronic Components, Crystals, Composites, Biomaterials, Sintered Carbides, Minerals, etc.” MICRACUT 152 has its place in virtually any metallurgical, geological, electronics, research, biomedical or industrial laboratory. The applications are endless.

MICRACUT 152 precision cutters are capable of cutting most materials such as, brittle or ductile metals, hard or soft metals, composites, ceramics, rocks, biomaterials, laminates, etc. They are designed for cutting all types of materials with minimal structural deformation. The structural integrity of the sample is maintained through MICRACUT 152's design and operation. Additionally, low kerf-loss and sample holding versatility makes the MICRACUT 152 an essential part of the modern day laboratory. The cut surface is ready for microscopic examination with minimal polishing.

- Modern and sturdy design

- Easy to use control panel with ergonomic turn-knob

- Precise micrometer with digital readout

- Gravity feed system

- Automatic stop at the end of cut

- Transparent protection hood with magnetic safety switch

- Inbuilt recirculation coolant tank